FILTREXX PRODUCT SELECTION GUIDE

Trying to pick the right compost sock for your job? Our Product Selection Guide helps you determine the best fit.

Filtrexx has engineered a complete line of compost sock materials for different job site conditions. Our new product selection guide helps you determine the best fit for your job, based on tensile strength testing and a few common site or project conditions.

ABOUT TENSILE STRENGTH

Confused by tensile strength and want to make sure you have the right strength for your job? Read our new guide and learn why we updated our standard test method:

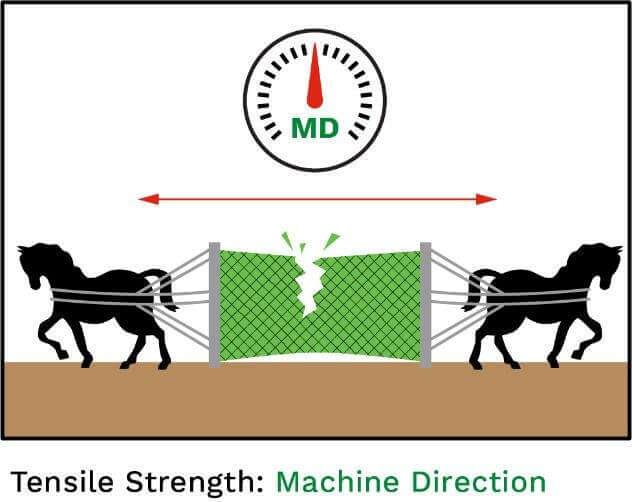

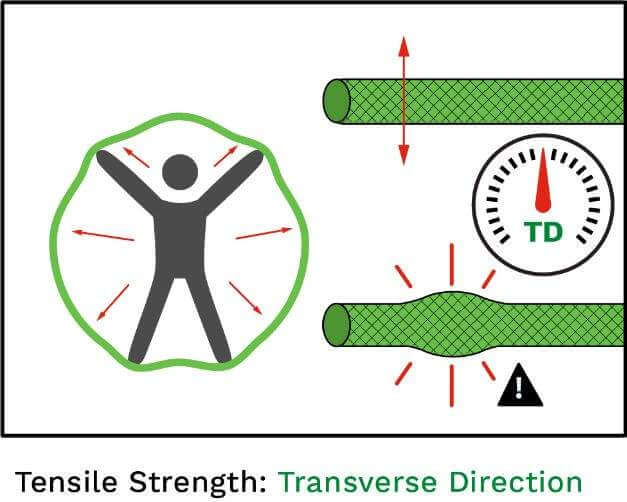

What is tensile strength? Tensile strength is the amount of force needed to break a material when stretching it apart.

How is tensile strength measured? Tensile strength is measured in units of pounds per square inch (cross sectional area). In the case when the material is very thin, like film and fabric, tensile strength is measured in pounds only.

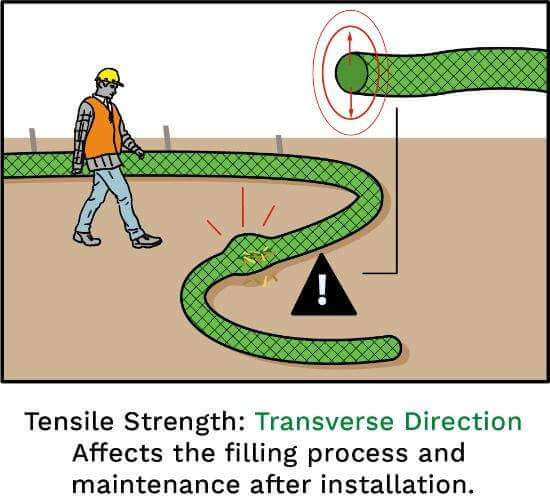

Filtrexx now uses the test method ASTM D4595 – Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method. This test method is the most accurate for testing loose knit materials used for compost sock mesh. This test method measures both machine direction (MD) and transverse direction (TD). MD measures the strength and resistance of the mesh from breaking when pulled lengthwise. TD measures the strength and resistance of the mesh from breaking when pulled widthwise.

Why is tensile strength important? Poor tensile strength can lead to compost filter sock mesh rupturing or even completely falling apart when removed from a pallet, moved from one location to another, during the installation process, or even once storm water flow contacts the product. MD affects the filling, palletizing, and installation process of compost filter sock. TD affects the filling process and maintenance after installation of compost filter sock.

Filtrexx has engineered a line of mesh products with various tensile strengths to meet specific applications and site conditions. To learn more about tensile strength and our research, read Filtrexx TechLink #3342, Tensile Strength Testing for Filtrexx Mesh Materials.

CONSIDER YOUR PROJECT SITE CONDITIONS

A number of typical site conditions may help you determine the best mesh for your job.

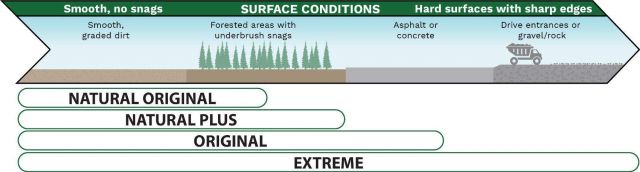

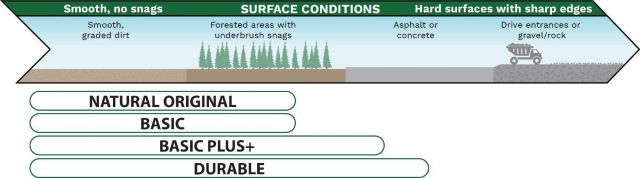

Surface Conditions:

What is your job site surface like – smooth or rugged?

Filtrexx SiltSoxx:

Blower Truck Mesh:

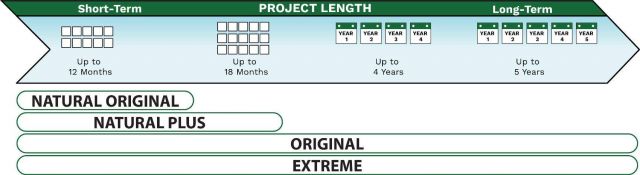

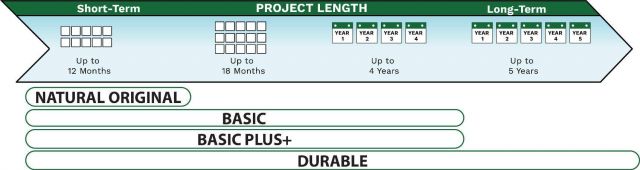

Project Length:

What is the length of your project? Consider using natural, biodegradable materials for short- term projects. For long-term projects, use longer lasting multifilament polypropylene materials.

Filtrexx SiltSoxx:

Blower Truck Mesh:

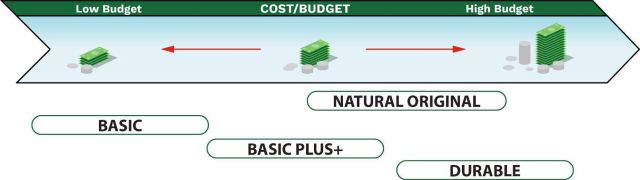

Project Budget:

Your project budget may help you decide the best material for your job.

Filtrexx SiltSoxx:

Blower Truck Mesh:

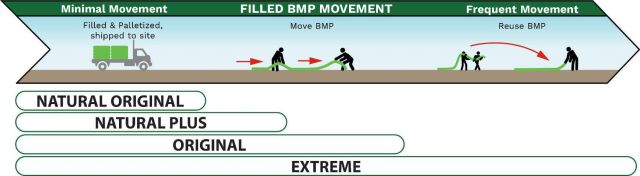

Filled BMP Movement:

Additionally, for pre-filled BMPs, you may want to consider if the BMP will be moved or not.

Filtrexx SiltSoxx: